How Membrane Switches Enable Lightweight and Sturdy User Interface Solutions

How Membrane Switches Enable Lightweight and Sturdy User Interface Solutions

Blog Article

The Ultimate Resource on Membrane Layer Switches Over: Layout, Performance, and Applications

Membrane switches act as an appealing junction of design and performance, playing a critical role in contemporary interface across numerous sectors. This source unloads the essential elements that add to their effectiveness, consisting of visuals overlays and circuit traces, while also elucidating the mechanisms behind their stress activation. As we check out the diverse applications of membrane buttons, it ends up being noticeable that their adaptability and toughness are vital in settings ranging from medical care to customer electronic devices. However, the nuances of their style and operational concepts may expose also much deeper understandings worth taking into consideration.

Recognizing Membrane Layer Switches

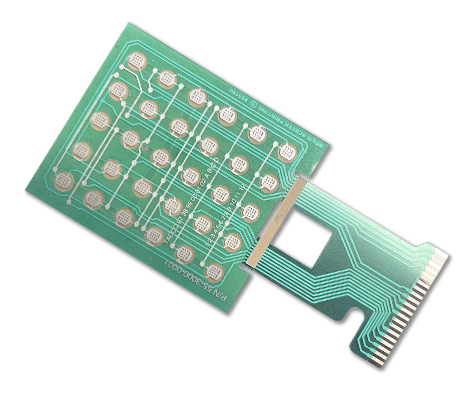

Membrane buttons are a sort of customer interface technology widely utilized in various electronic devices, identified by their slim, flexible style and functionality. These switches consist of several layers that consist of graphic overlays, sticky layers, and wiring, allowing a small and effective user interface for individuals. They can be found in appliances, medical tools, and industrial control panels, offering a reputable method for individual communication.

Among the main advantages of membrane layer switches is their ability to withstand impurities such as dirt and moisture, making them ideal for atmospheres where toughness is crucial. Their inconspicuous style permits for seamless assimilation into various applications, while the personalized graphic overlays boost individual experience by offering clear visual responses. In addition, membrane layer buttons can accommodate a selection of technologies, such as tactile comments and backlighting, additional boosting their use.

The manufacturing process for membrane layer changes generally includes display die-cutting, lamination, and printing methods, making sure precision and consistency in production. Generally, membrane layer changes represent a functional and effective service for modern digital devices, incorporating capability with aesthetic appeal in user interface layout.

Secret Elements and Design Elements

A range of key components and design elements come with each other to create a reliable membrane button. At the core, the visuals overlay serves both functional and visual objectives, offering an easy to use user interface while safeguarding internal components from ecological variables. The choice of materials, typically polyester or polycarbonate, affects sturdiness and responsive comments.

Under the overlay, the sticky layer makes certain the switch adheres safely to the substrate, which can be glass, steel, or plastic. The spacer layer is vital, as it preserves the needed void between the overlay and the circuit layers, enabling efficient actuation. Membrane Switches. Circuit traces, usually made from conductive ink or adhesive, are printed on a flexible substratum, allowing electric signals to be sent when pressure is used

Layout considerations also include the plan of tactile domes or embossing that give physical feedback to the user, boosting the overall experience. Additionally, the layout and spacing of the switches should be optimized for convenience of use, making certain that individuals can navigate the user interface with ease. Generally, these components and style elements work synergistically to create a trusted, practical membrane button customized to certain applications.

Performance and Operation Device

At the heart of reliable functionality for membrane changes exists their operational mechanism, which facilitates individual interaction with a straightforward yet reliable style. These switches operate the principle of pressure activation, where a customer applies force to an assigned area of the button (Membrane Switches). This activity presses the layers of the switch, completing an electric circuit that sends a signal to the connected tool

The building normally includes a top graphic layer, see this an adhesive spacer layer, and a bottom circuit layer, which collectively create a durable interface. When pressure my sources is applied, the top layer collapses versus the lower circuit layer, enabling conductive traces to connect. This design not just enables clear responsive responses however also ensures longevity and dependability, as the buttons are usually immune to dirt and wetness.

Moreover, the flexibility of membrane switches over allows for assimilation with numerous modern technologies, consisting of LED indications and microcontrollers, boosting their functionality. By providing a structured user interface that lessens mechanical wear, membrane layer switches continue to be a favored option in applications ranging from consumer electronic devices to industrial tools, making sure optimum efficiency and individual satisfaction throughout varied settings.

Kinds of Membrane Layer Buttons

Another significant classification is brightened membrane layer switches, which include backlighting to enhance exposure in low-light problems. These buttons are typically utilized in control panels and dashboards where clear presence is important.

Additionally, there are customized membrane changes designed to satisfy specific dimensional, graphical, and functional needs. These personalizations can consist of unique shapes, shades, and layouts, enabling smooth combination right into numerous gadgets.

Applications Throughout Different Industries

Just how do membrane buttons enhance capability throughout varied industries? In the clinical sector, membrane layer buttons play a critical role in tools such as diagnostic equipment and patient surveillance systems, where integrity and convenience of cleaning are critical.

In the automobile sector, membrane switches are generally used in dashboards and control board, offering instinctive controls that boost chauffeur security and comfort. The customer electronics industry likewise benefits from their customizable and lightweight attributes, making it possible for sleek designs for mobile phones and home appliances.

In addition, membrane layer switches locate read this post here applications in industrial automation, where they add to reliable machinery operation and surveillance systems. Their resistance to dust and moisture makes certain functionality sought after problems (Membrane Switches). Furthermore, the food and beverage industry utilizes membrane buttons for equipment control, where health and longevity are vital

Verdict

Finally, membrane switches stand for an important technology in interface modern technology, characterized by their distinct layout and capability. Their crucial parts, including visuals overlays and circuit traces, add to their functional effectiveness through stress activation. The convenience of membrane layer changes promotes their application across diverse markets, from medical tools to customer electronics. This comprehensive understanding strengthens the relevance of membrane layer buttons in improving product use and resilience in contemporary technological atmospheres.

Membrane layer changes offer as a fascinating junction of layout and performance, playing an essential role in modern-day user interfaces throughout different sectors.Membrane layer switches are a kind of customer interface modern technology extensively used in different electronic gadgets, identified by their slim, flexible layout and performance.At the heart of efficient functionality for membrane layer changes exists their operational system, which helps with user communication via a basic yet effective layout. These switches operate on the concept of stress activation, where an individual applies force to an assigned area of the button.In final thought, membrane switches over stand for an important innovation in customer interface modern technology, defined by their special design and functionality.

Report this page